Light-Weight Pinnacle Seat

Services

Industrial Design, Engineering, Prototyping, Manufacturing, Production

Client

B/E Aerospace

The best selling, and lightest aerospace seat on the market.

With fuel prices increasing B/E Aerospace needed a familiar product design firm with long-term experience in the aerospace industry that could create a main cabin economy seat that was lighter than anything else on the market. The team would need to integrate passenger comfort, alternative materials, and a revolutionary approach to aerospace seat engineering. In addition to providing unparalleled fuel efficiency, this seat would also need an aesthetic that complements the next generation of aircraft interiors and one that could be scaled to fit within a wide range of aircraft body sizes. To validate the designs, gain the necessary approvals and solicit customers we would also be developing a series of prototypes throughout the product development cycle.

Solution

Drive weight out of the product without sacrificing comfort or reliability.

result

The lightest-weight seat on the market, which paid for itself in fuel savings in one year.

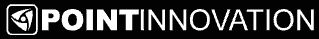

Suspension System

New suspension system flexes under the weight of the occupant, providing a more comfortable seating, and thus allowing for reduced cushion foam thickness.

Composite Back and Seat

First in aircraft seating to use lighter, thinner, and just as durable Crystal Flex material.

Hydra-lock

Occupant’s center of gravity was optimally balanced based on ergonomic studies, which lead to more accurate load distributions at the pivot.

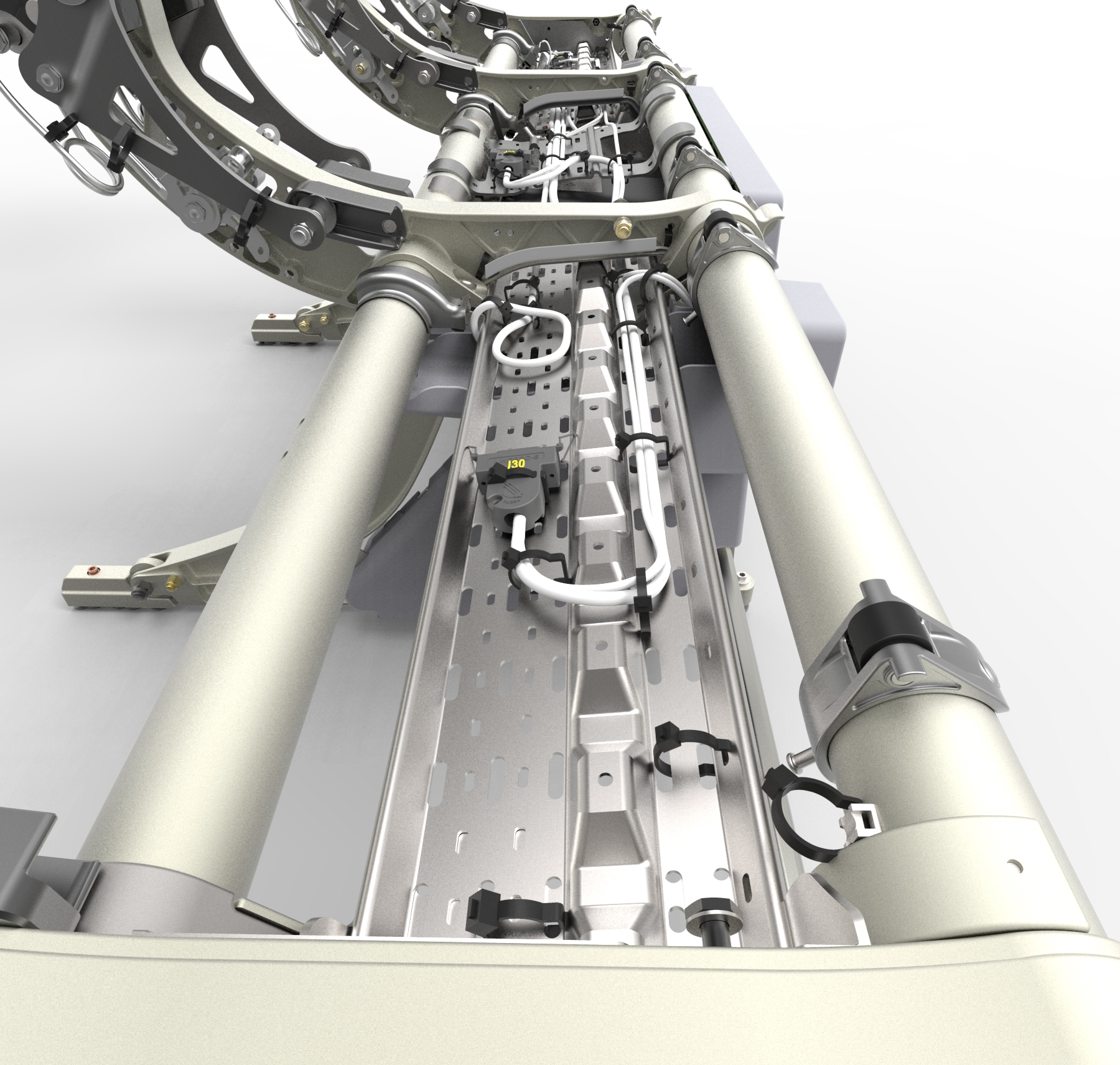

Common Parts

Seat frame structure was designed to have common parts across multiple platforms. This created more living space for the passengers, and also resulted in big savings when undergoing certification.

Space Increase

Implementation of weight reducing and common part features created extra room for IFE package, and enabled our team to come up with a very efficient wire management system.