About

a focused, cohesive team of designers and engineers

Our Process

1

scoping & discovery

The team identifies whether there is an appreciable need for the client’s idea to be developed into a viable product, and what limitations might be involved in the development process. Using statistical data, at this stage we validate the opportunity, as well as the competitive landscape. That includes collecting relevant statistics, such as demographics, to gauge customer potential and identify possible risks. Research gained at this point gives us a better understanding of what the development path should look like, with enough clarity to project a feasible scope of work, timeline and budget.

2

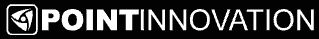

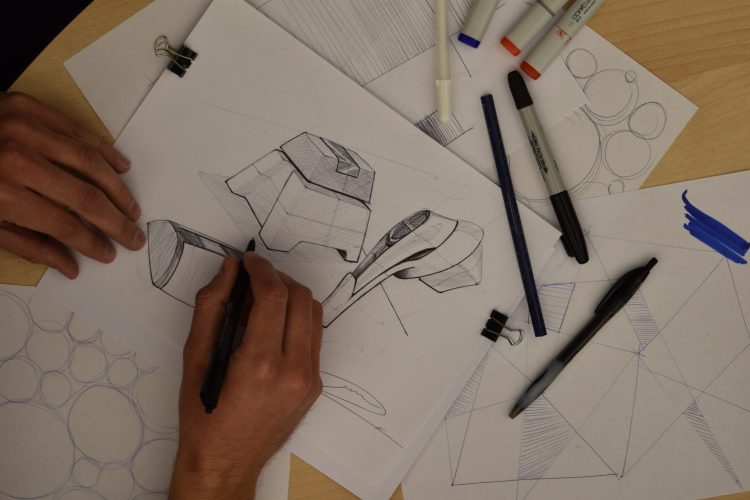

Concept Development

Next we brainstorm to define and outline design parameters and constraints, based on findings from Scoping and Discovery. Here is where concept ideation begins, design and engineering are evaluated, and design is refined, defined, and detailed. At this stage preliminary materials, colors, and finishes are selected for the final concept, and a preliminary model is created as part of the sequential process.

3

Concept Evaluation & Refinement

Our third stage gives the product further detailed and comprehensive development. Significant design issues, if any, are addressed and resolved at this point through DFMA methodology. Prototypes are built considering design and functionality as well as regulatory compliance, then tested to validate user compatibility. Through this DFM stage, tooling is customized, and manufacturing/production costs are estimated and reviewed to ensure that form, fit, and function requirements of the product have been optimized.

4

Deployment & Monitoring

At this stage we validate and verify the functionality of the product design for full operating capability. This is a low volume pre-production build that is representative of what the final production will be. The pre-pilot and pilot build phases are used to change or modify methods, test processes, and discover any issues before a large volume of product is manufactured.

3

Concept Evaluation & Refinement

Our third stage gives the product further detailed and comprehensive development. Significant design issues, if any, are addressed and resolved at this point through DFMA methodology. Prototypes are built considering design and functionality as well as regulatory compliance, then tested to validate user compatibility. Through this DFM stage, tooling is customized, and manufacturing/production costs are estimated and reviewed to ensure that form, fit, and function requirements of the product have been optimized.

5

Maintenance & Support

our leaders

Monte Curran

Monte Curran

Kip Harkness

Kip Harkness

ANDREW MAFFETT

ANDREW MAFFETT

Monte Curran

Monte Curran

Kip Harkness

Kip Harkness

ANDREW MAFFETT

ANDREW MAFFETT

25 years of

History

In 1993, after years of honing his skills as a mechanical engineer employed for both national and international companies, Monte Curran accepted a position with an industrial design firm specializing in product development. Little did he anticipate that with this career move, the trajectory of his future would change. Curran discovered that despite their many impressive accomplishments, his new employer wasn’t receptive enough to their clients’ needs. He could do better.

In 1995, Curran founded his own engineering company, Product Development Services (PDS). His wide range of experience gave him a unique perspective on driving innovation and growing the company using industrial design services for product development, and utilizing CAD and 3D modeling. Over time, his hand-picked talented team and ongoing, long-standing business relationships led to diversifying into other industries, such as telecommunications and medical products. Curran also carved out a niche in the aerospace industry, designing seating for commercial airlines world-wide.

In 2002, PDS was relaunched as Point Innovation, and a relocation from Dallas to Lewisville, Texas, marked a new chapter of growth and accomplishment for the consultancy. With a growing portfolio of work and additions to our staff, by 2014 we outgrew our space and moved to a 12,000 square foot facility in Lewisville, our present location.